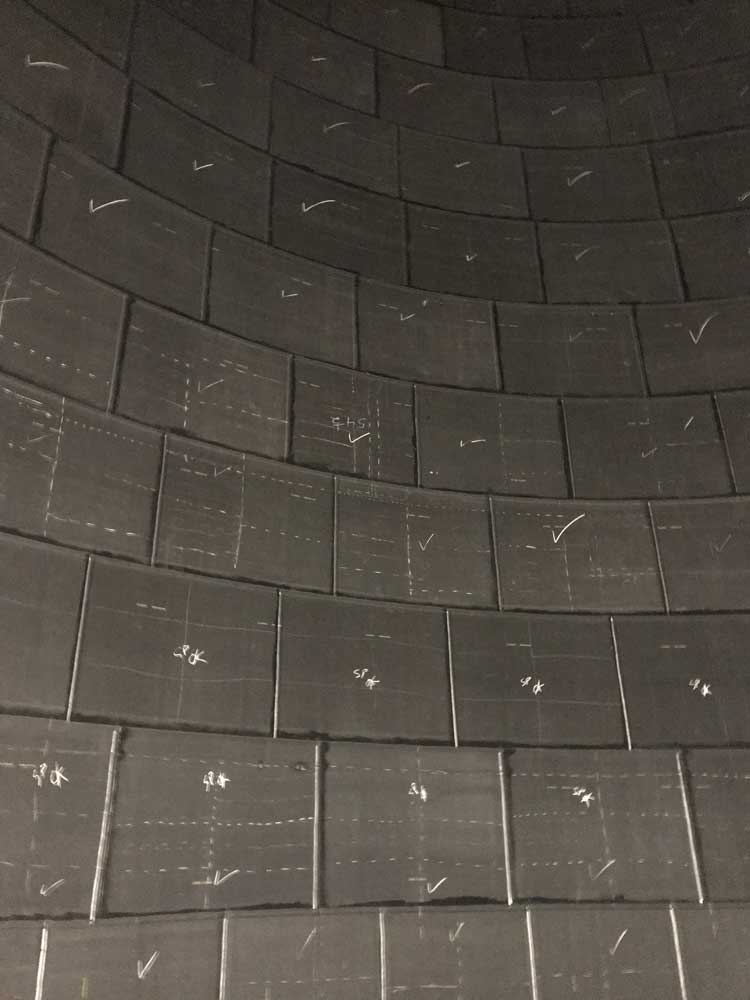

Rubber LiningFor over 70 years, rubber and other polymers have been used to line pipes, tanks and equipment to protect against corrosion and abrasion. Chemical processing, mining, water treatment and other processes require materials to protect against harsh acids, alkalis and abrasives – often at elevated temperatures. Selection of the right material is critical and Spence engineers can ensure that optimal choices are made. Installation and curing of these linings is critical for in-service performance. With over 100 years of combined service in the rubber lining industry and practical experience across Canada and around the world, Spence personnel will perform all work according to detailed work instructions and manufacturer’s specifications. |

||

|

|

Select Lining Materials and Characteristics:

|

|

Installation You Can TrustSurface Preparation

Procedures

Experience

|

||

|

|

Equipment Lined:

|

|

|

Versatility in Applications: Rubber linings are indispensable across various industries due to their exceptional versatility and protective qualities. The superior quality of rubber employed by Spence Corrosion enhances the durability of equipment and structures, shielding them from corrosive substances, abrasive materials, and harsh operating conditions. The versatility of rubber linings extends to:

|

|